Overview of PTFE High-Frequency Laminates

PTFE high-frequency laminates have experienced rapid growth in China’s electronic information and high-tech industries in recent years. This sector, in particular, has seen unprecedented growth opportunities, with major manufacturers increasing research and development investments while launching innovative products. During this period, domestic PTFE high-frequency laminate manufacturers, such as Shengyi, Huazheng New Materials, Wangling, Guoneng, and Fushide, have emerged, continuously developing new types of high-frequency laminates.

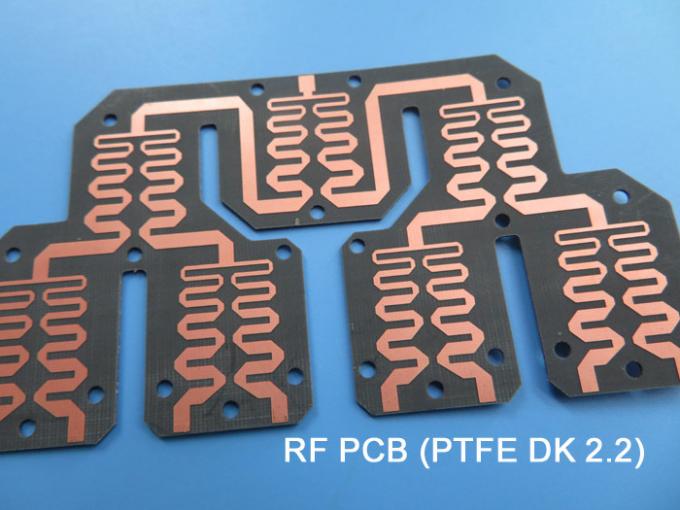

Why PTFE High-Frequency Laminates?

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is widely used in high-frequency applications. PTFE laminates are essential in meeting the demanding requirements of high-frequency communications. Both the dielectric properties and processability of PTFE must be considered during the production process. Known for its exceptional corrosion resistance and outstanding engineering plastic properties, PTFE has become the material of choice for:

- High-speed digital circuits

- High-frequency, broadband, and wireless RF (Radio Frequency) applications

These properties make PTFE highly suitable for applications in fields such as:

- Radio communications

- Military

- Commercial aviation

- Semiconductor testing equipment

Leading Suppliers of PTFE High-Frequency Laminates

Globally, leading suppliers of PTFE high-frequency laminates include Rogers, Arlon, and Taconic. In China, domestic leaders include Wangling, Zhongying, Huazheng, Fushide, and Guoneng. However, due to PTFE’s relatively soft texture and the use of glass cloth reinforcements and ceramic fillers, its cutting performance is not on par with FR4.

Challenges in the Drilling Process

PTFE’s cutting characteristics present challenges during the drilling process. Issues such as burrs, flash, and incomplete glass cloth cutting can occur, leading to:

- Tool binding

- Material delamination

- Poor hole quality

These challenges negatively impact the quality of metallized holes, leading to voids or copper bumps. As a result, careful attention is required during the drilling process to ensure high-quality production.

Drilling Process for PTFE High-Frequency Laminates

The drilling process for PTFE high-frequency laminates must adhere to strict quality control standards. The following requirements ensure that the drilling process meets the desired specifications:

- Hole wall roughness must be controlled to ≤40 µm.

- No burrs should be present inside the hole, and the hole edge should be free of flash.

- The white area at the hole entrance must be ≤2.0 mm from the edge of the hole.

- The hole shape should remain normal, without any deformation.

- After electroplating, the hole walls should be free of plating bumps, or any bumps should not affect the board’s performance.

Given the high-frequency board’s strict requirements for copper foil surface roughness, no burrs, flash, or other surface defects are acceptable. Moreover, PTFE’s relatively soft resin can lead to material deformation during drilling, which can result in incomplete glass cloth cutting and excessive pulling forces, causing delamination and whitening of the laminate.

To address these challenges, it is recommended to use thick aluminum sheets and high-density pads during drilling to effectively prevent burrs, flash, and whitening issues.

Our Expertise in High-Frequency PCB Manufacturing

As a professional manufacturer of 1-40 layer high-frequency PCB circuit boards, we offer expedited production for various types of PCBs, including:

- High-frequency boards

- Specialty circuit boards

- Microwave RF boards

- Antenna boards

We also maintain stock of materials such as Rogers, Taconic, F4B, TP-2, and FR-4, with dielectric constants ranging from 2.2 to 10.6. If you have any specific requirements or need more information, please feel free to contact us

written by

steve ran

Senior Layout Manager