Why Choose HXD as Your Copper Core PCB Manufacturer?

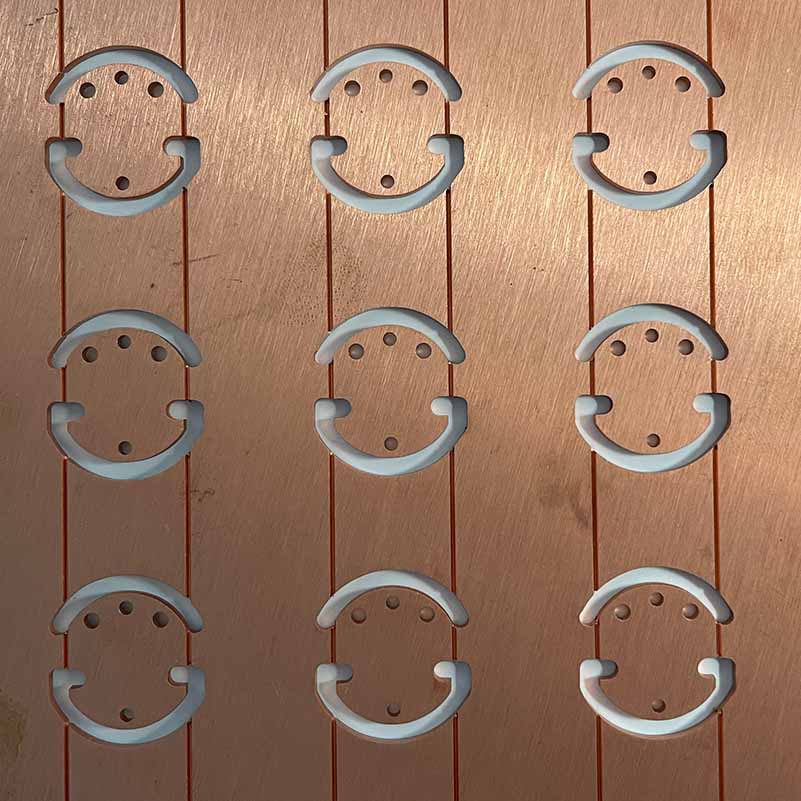

Thermoelectric Separation Technology: HXD utilizes an advanced process to allow the thermal pads to have a “zero distance” connection to the copper substrate. This structure provides thermal performance near the physical limit for high power products.

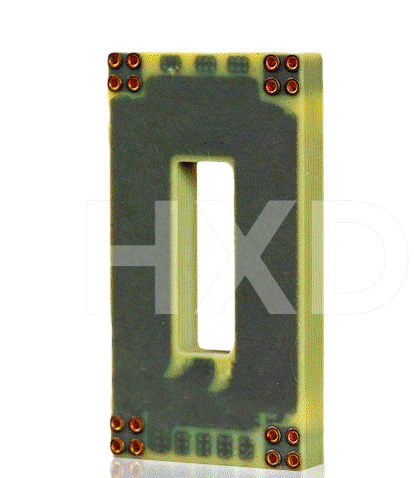

Pedestal Technology: We have high-precision copper etching technology to produce raised copper structures. Components can be mounted directly on the copper core. This greatly improves heat transfer and provides excellent grounding and signal stability.

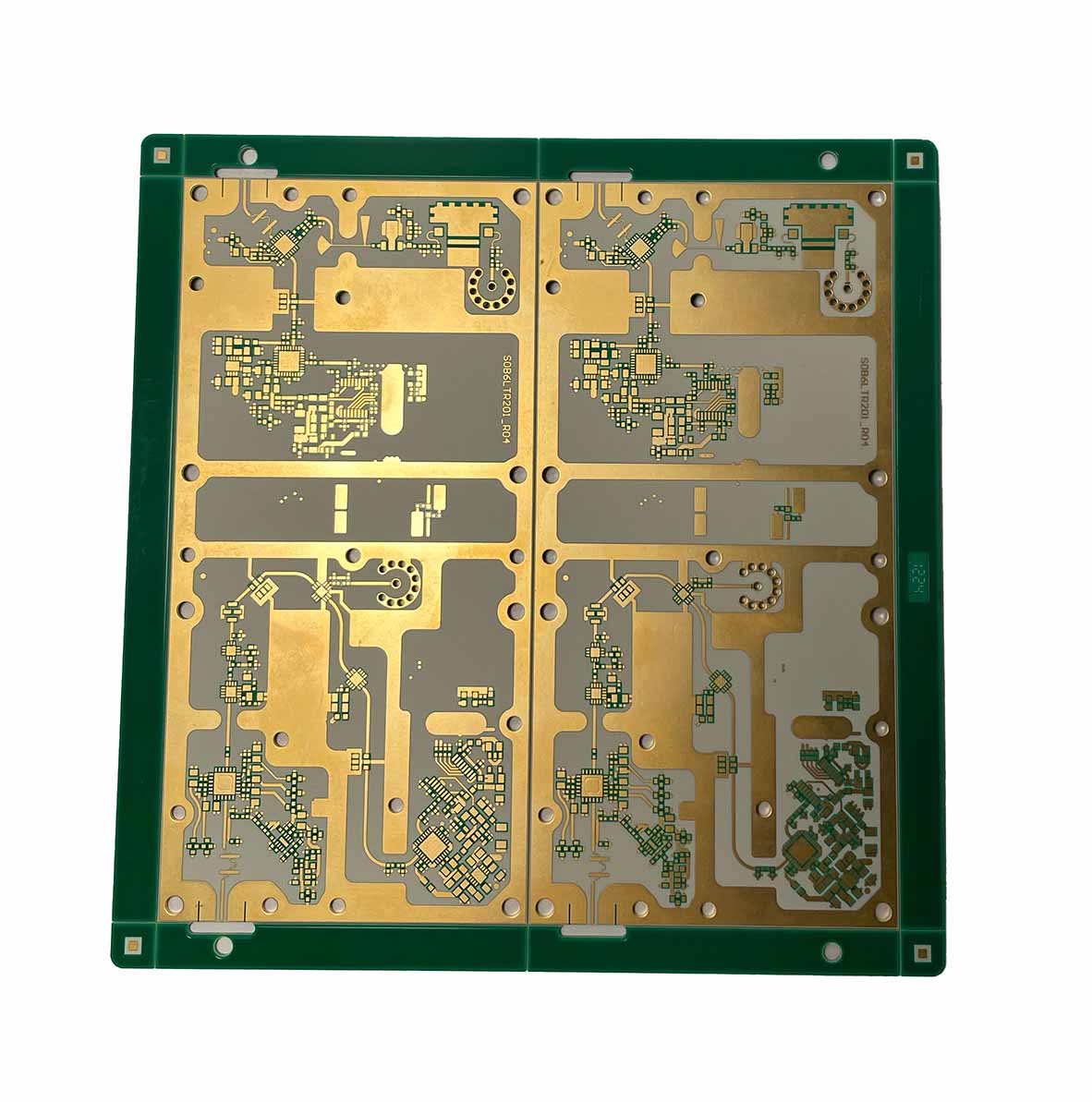

All surface finishes are available: ENIG, silver, HASL and OSP.