Advantages of HXD as a PCB Fabricator

We not only produce Flexible PCBs, but we are also committed to solving the physical limits of Flexible PCBs through advanced processes.

Materials

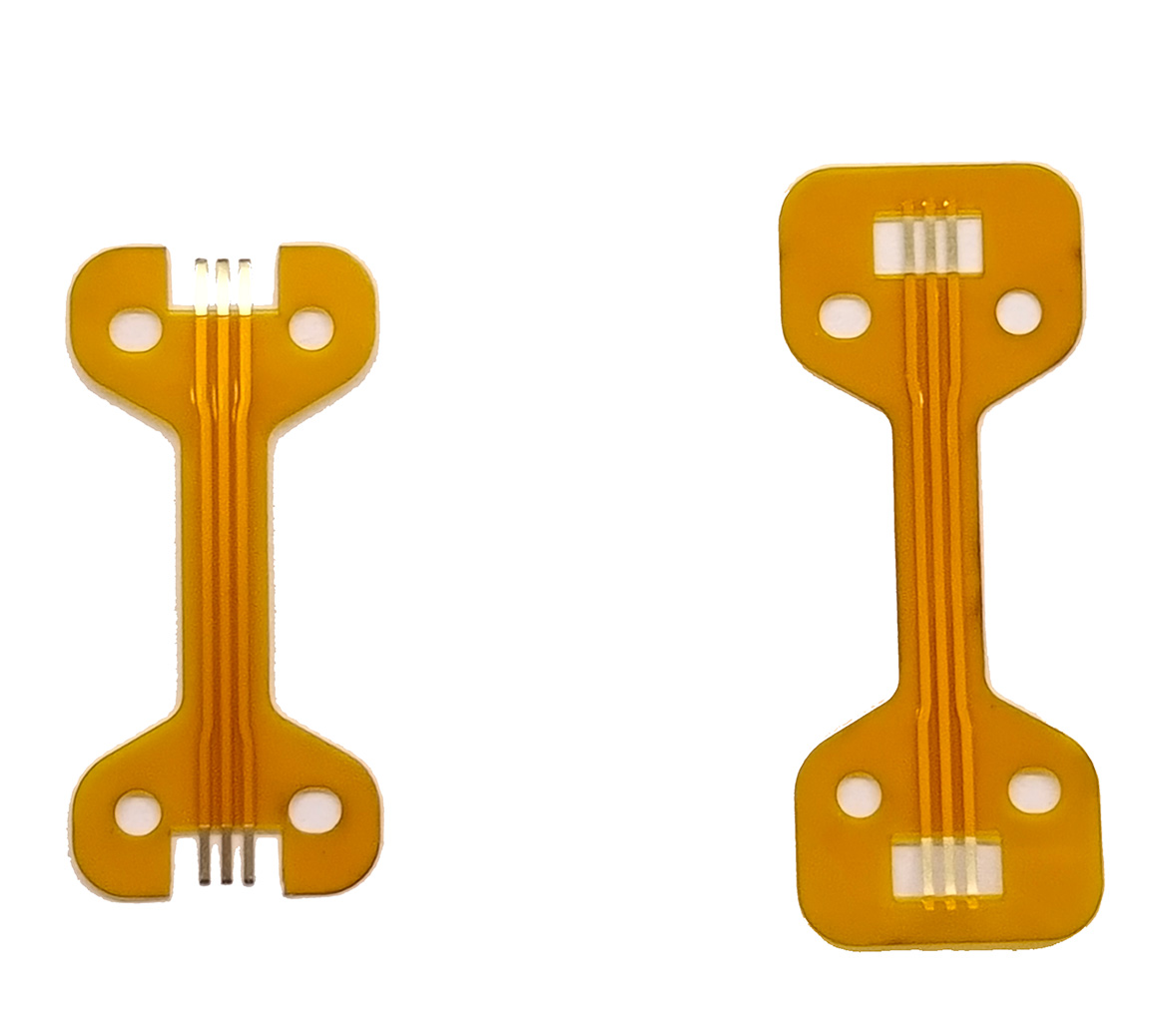

HXD uses high quality materials such as Dupont and Shengyi in Flexible PCB manufacturing, and also offers PCB stiffener including PI, FR4 and stainless steel. For dynamic bending requirements, we can also offer a highly flexible RA Copper solution that can support millions of 180° dynamic cyclic bends without cracking.

Equipment

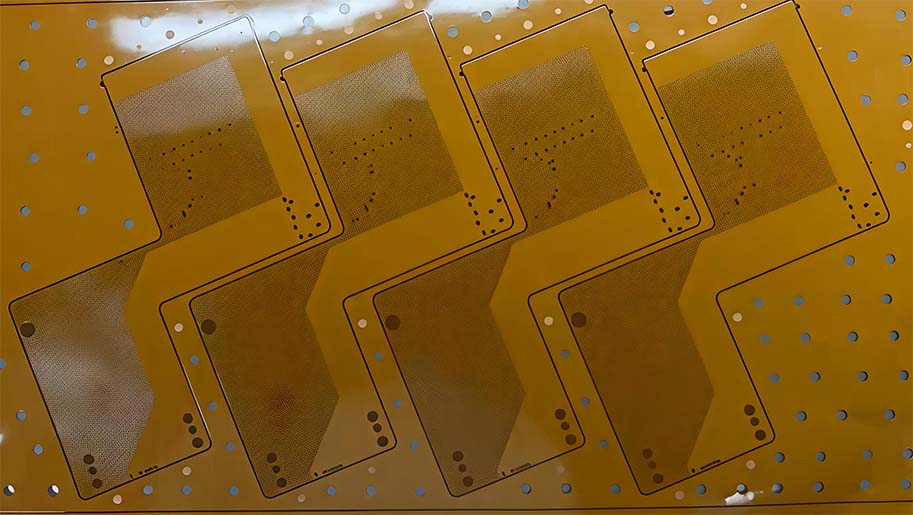

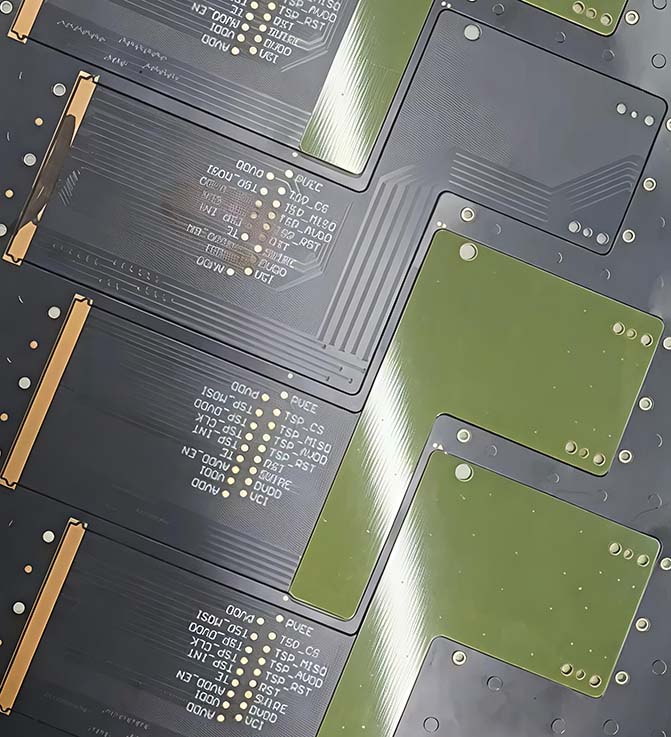

HXD has a complete range of Flexible PCB production equipment, including process equipment for copper lamination (FCCL), etching, laser and mechanical drilling, and surface treatment. High-precision UV laser technology enables blind vias as small as 0.075mm (3mil), providing more routing space for miniaturised devices.

Customisable

HXD offers custom Flexible PCBs, including 1 to 10-layer flexible boards, single-sided flexible boards, double-sided flexible boards, Rigid-Flex PCBs, and transparent flexible boards.