Why choose HXD's High Frequency PCBs?

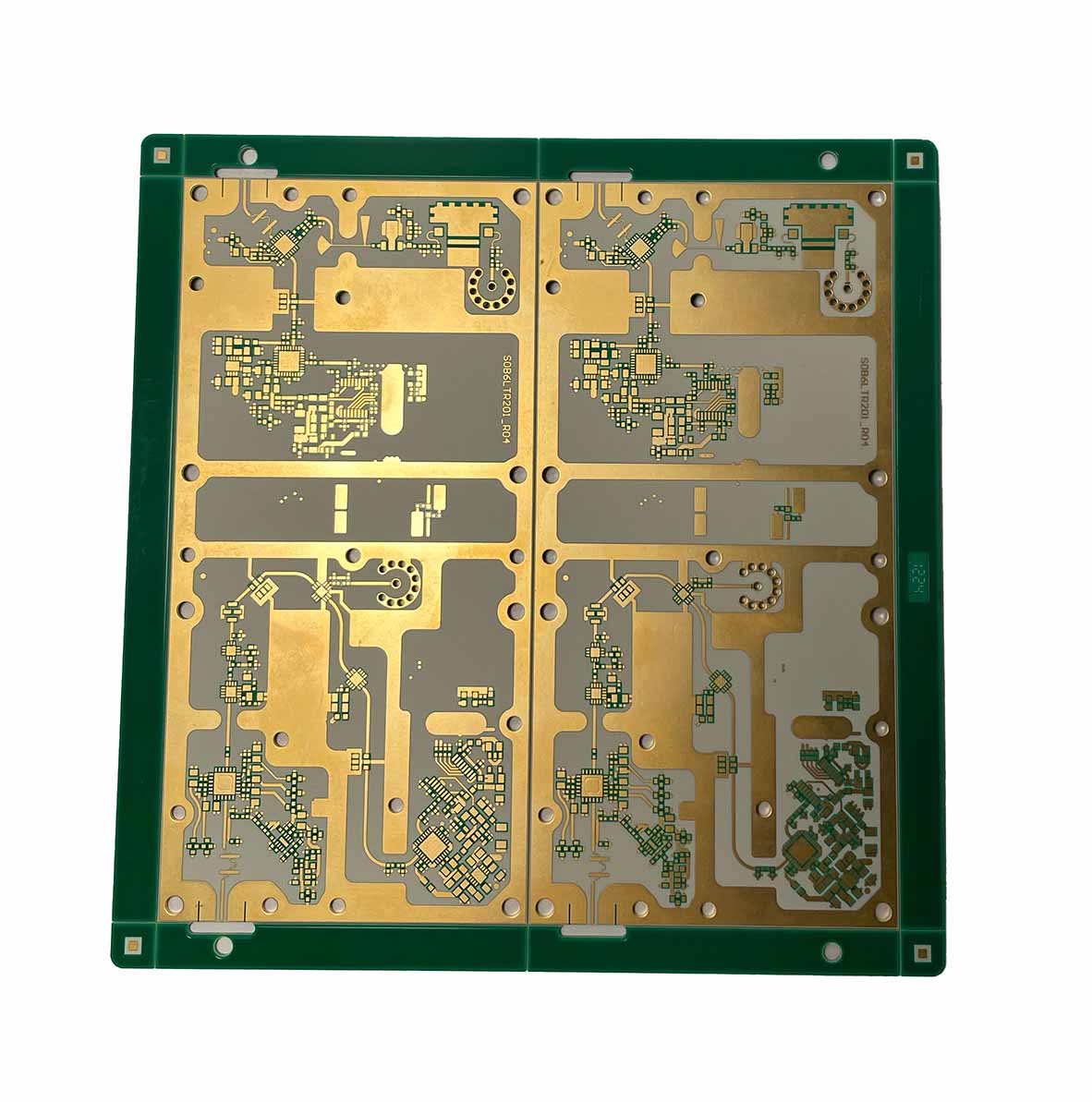

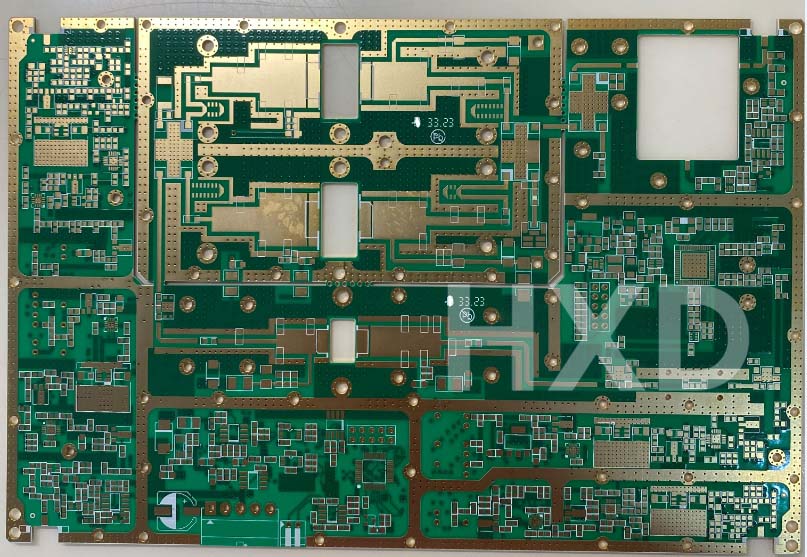

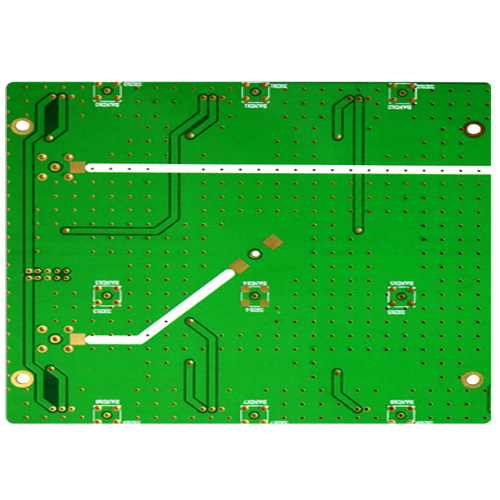

HXD has many years of experience in manufacturing high frequency PCB. We have the following technical advantages in design and manufacturing:

1. HXD can support the customer to check precise design of conductor geometry and layer stackup. By this way, it can ensure strict impedance control, guaranteeing signal integrity and transmission stability.

2.HXD produces such boards with high-precision manufacturing processes. HXD is capable of producing microvias and multilayer impedance-controlled boards. Depending on board stackup, we offer technical treatments such as backdrilling to ensure signal integrity.

3. HXD have different high-frequency materials and can make hybrid PCB (such as Rogers + FR4 hybrid layers). It can achieve a balance between high performance and cost. According to customer needs, we can choose different thicknesses and dielectric to meet various high-frequency applications.