Dielectric Layer control capacity

During fabrication of metal core LED PCBs, the dielectric layer determines directly the thermal resistance performance of PCB. HXD can stably achieve a dielectric layer of ≤75μm,effectively reducing thermal resistance between the copper traces and the metal substrate.This enables faster heat conduction and lower LED junction temperature.

Copper Foil Treatment Process

To avoid issues like copper foil lifting and delamination in high-power LEDs under repeated thermal cycling,HXD’s optimized lamination process with high-adhesive copper foil enhances significantly the bond strength between copper foil and the dielectric layer, it can meet stable demands of applications like street lights,industrial/mining lights, and automotive.

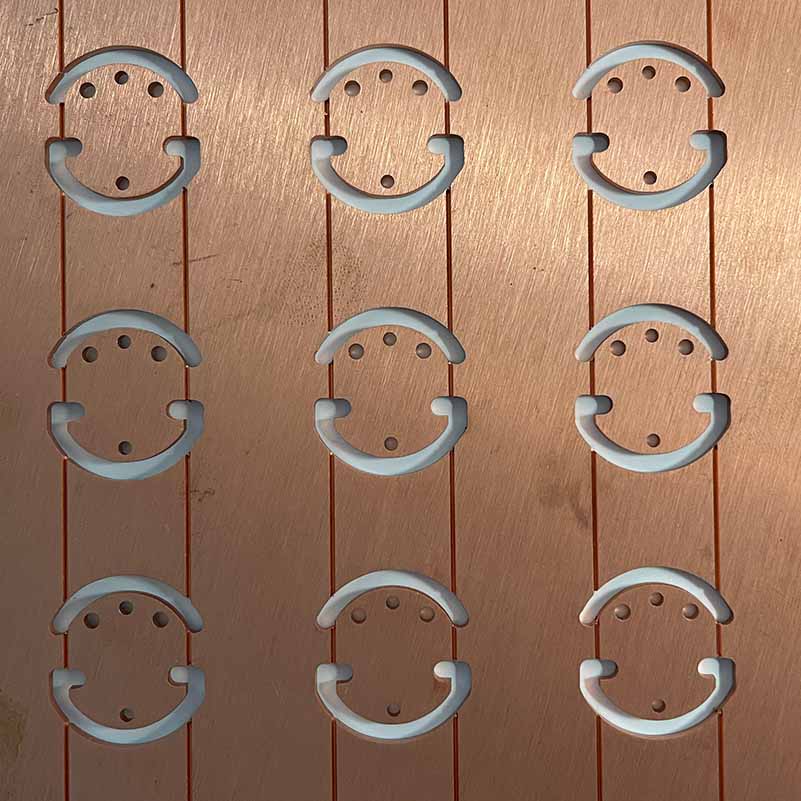

High Reflectivity Solder Mask Process

HXD offers white and matte white solder mask,it can effectively improve light reflectivity and reduce optical loss.