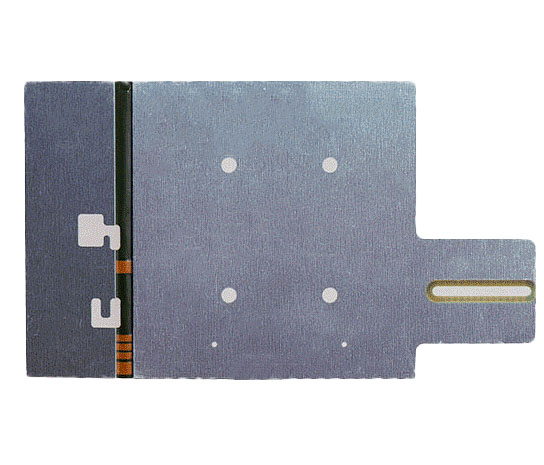

What is MCPCB?

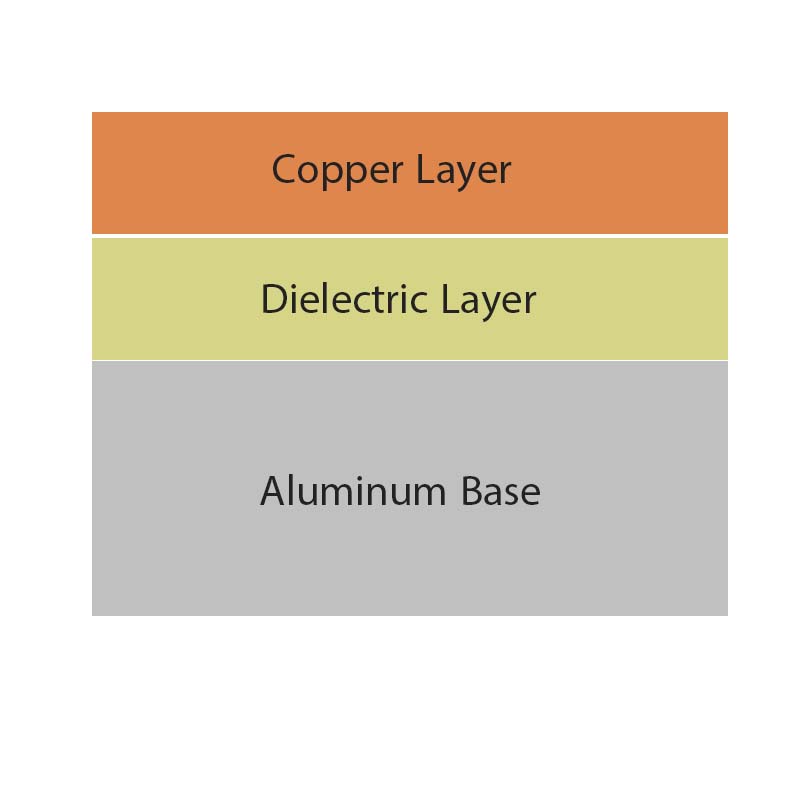

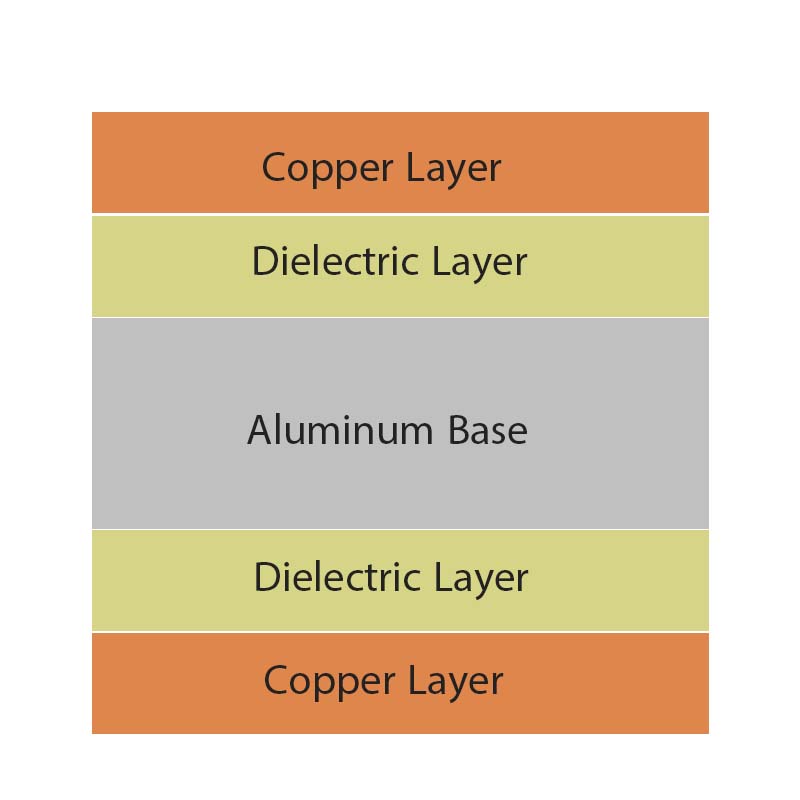

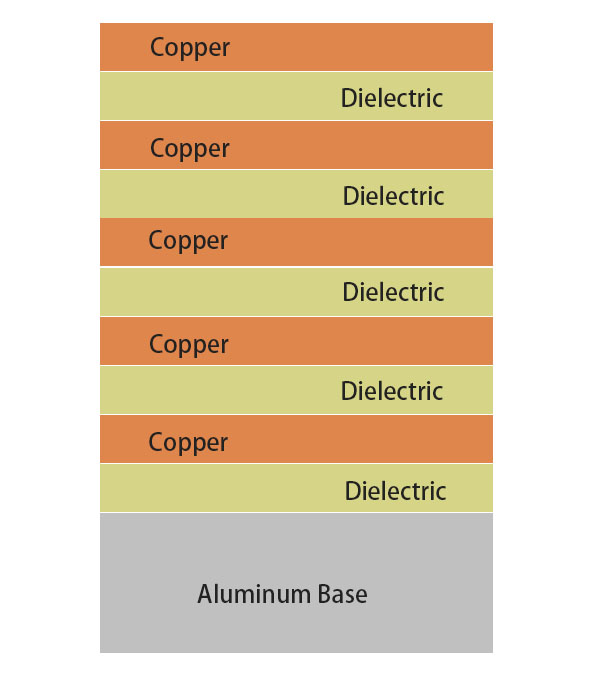

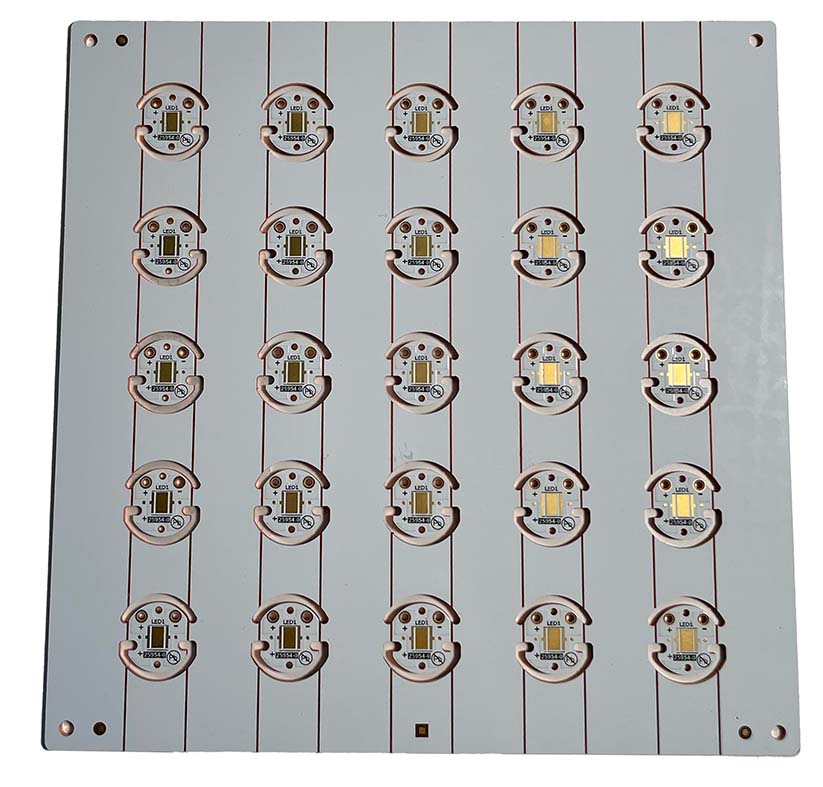

Metal Core Printed Circuit Board (MCPCB), also referred to as Insulated Metal Substrate (IMS) PCB or Thermal PCB, is a specialized type of PCB that differs from traditional FR4 boards by incorporating a metal base to enhance heat dissipation. During operation, electronic components generate heat, and the metal core efficiently channels this heat away from critical areas to less sensitive regions, such as metal heat sinks or the core itself.

The most commonly used metals for MCPCB cores are aluminum, copper, and steel alloys:

-

Aluminum provides excellent thermal conductivity and heat dissipation while remaining cost-effective, making it the preferred choice for standard MCPCBs.

-

Copper offers superior performance in heat transfer but comes at a higher cost.

-

Steel, including both regular and stainless steel, is mechanically stronger than aluminum and copper but has lower thermal conductivity.

The selection of core material depends on the specific application, taking into account thermal performance, mechanical rigidity, and cost. Considering these factors, aluminum emerges as the most practical and economical option for most MCPCB designs.