The Advantages of HXD Rigid PCB

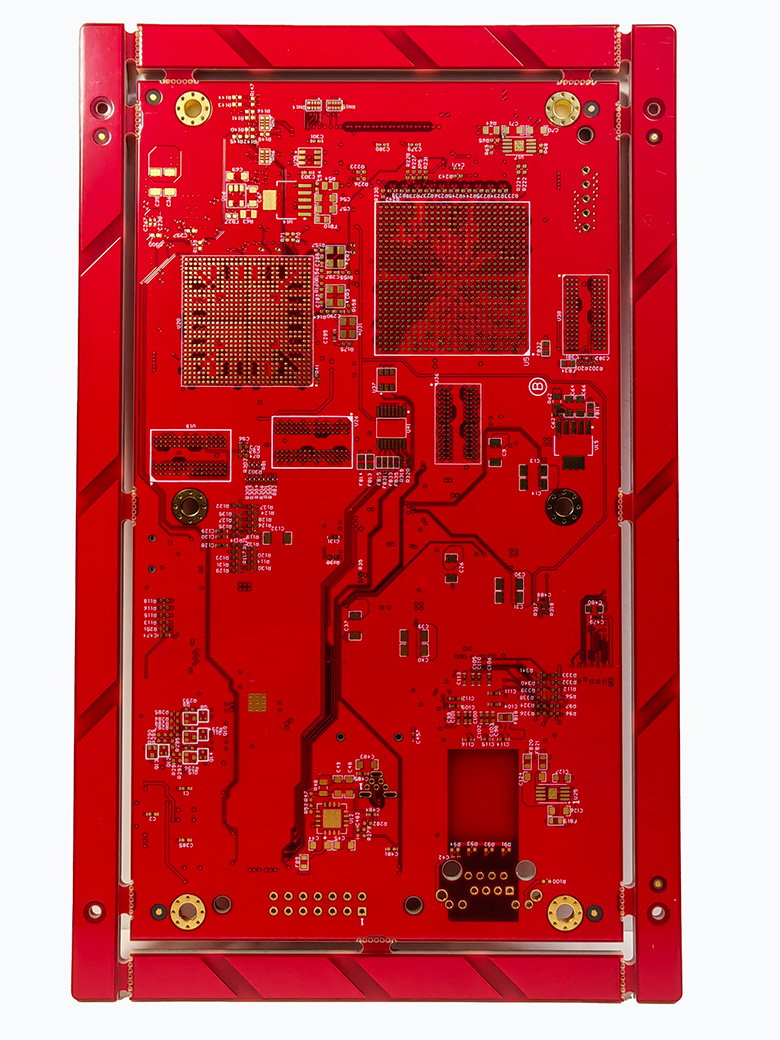

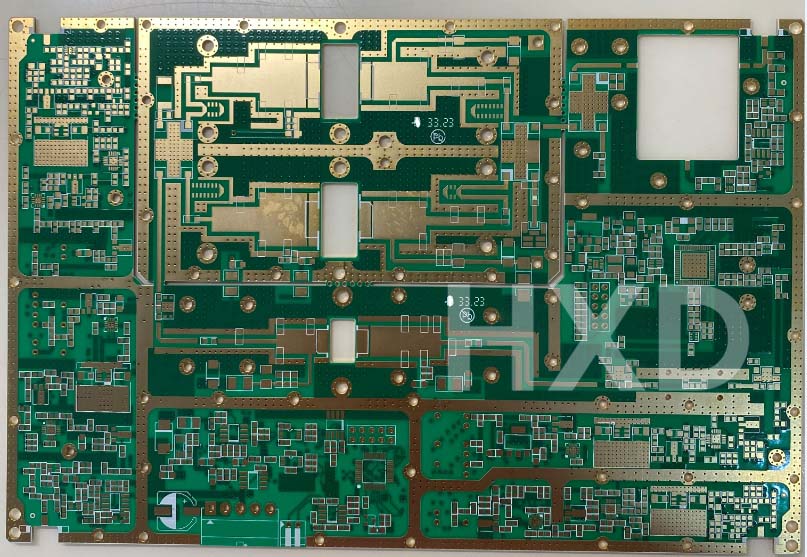

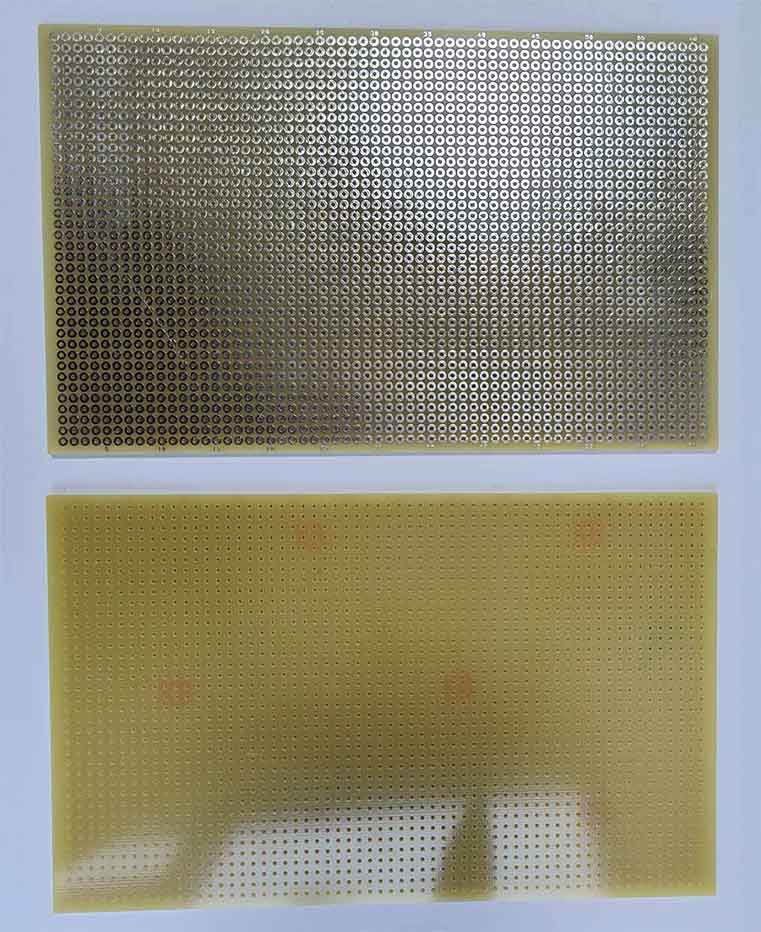

Stable Structure, High Mechanical Strength

The most significant advantage of Rigid PCBs relies on their robust construction, capable of supporting heavy electronic components. The PCB maintains excellent stability and resisting deformation throughout the product’s lifespan.

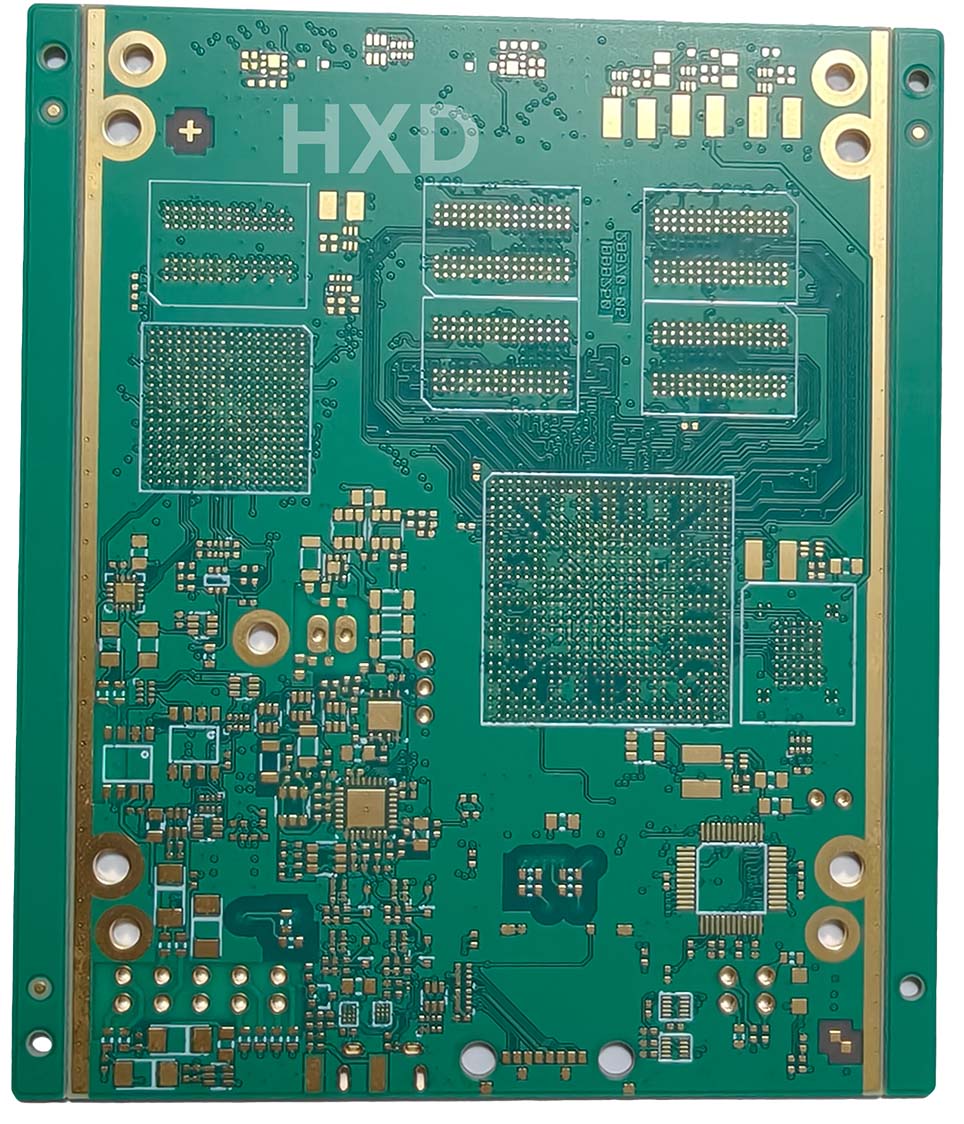

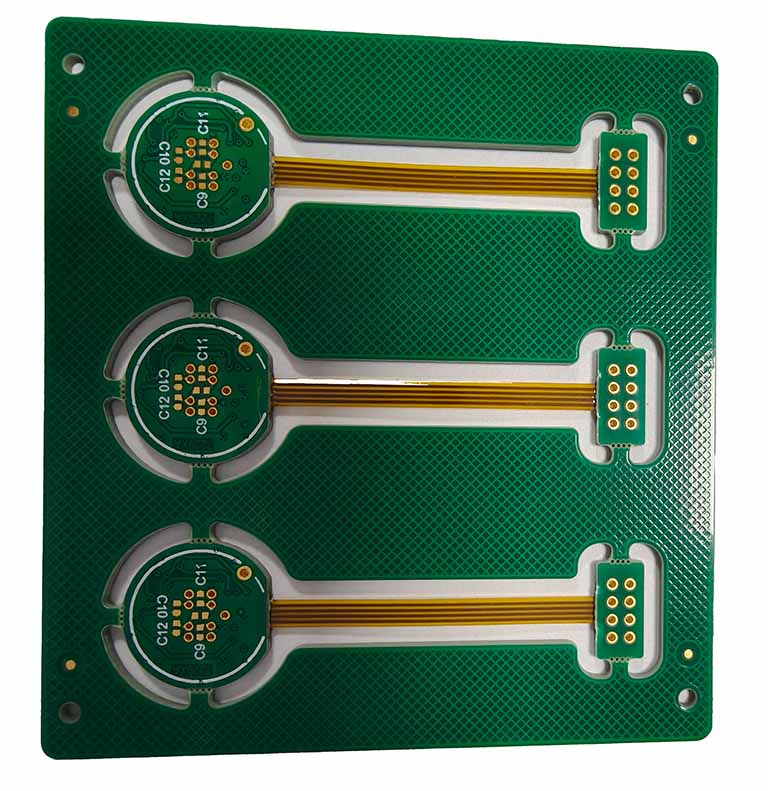

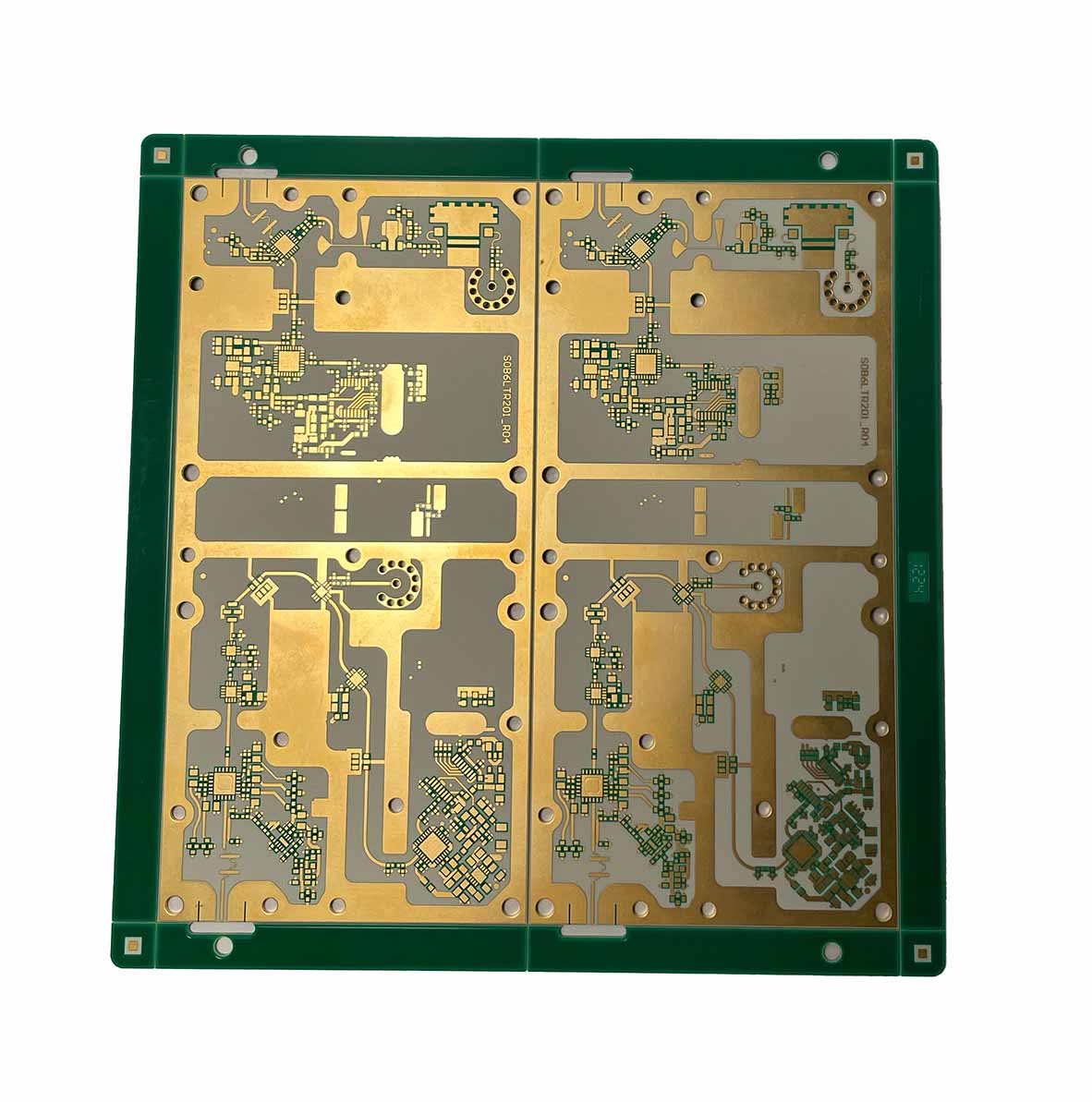

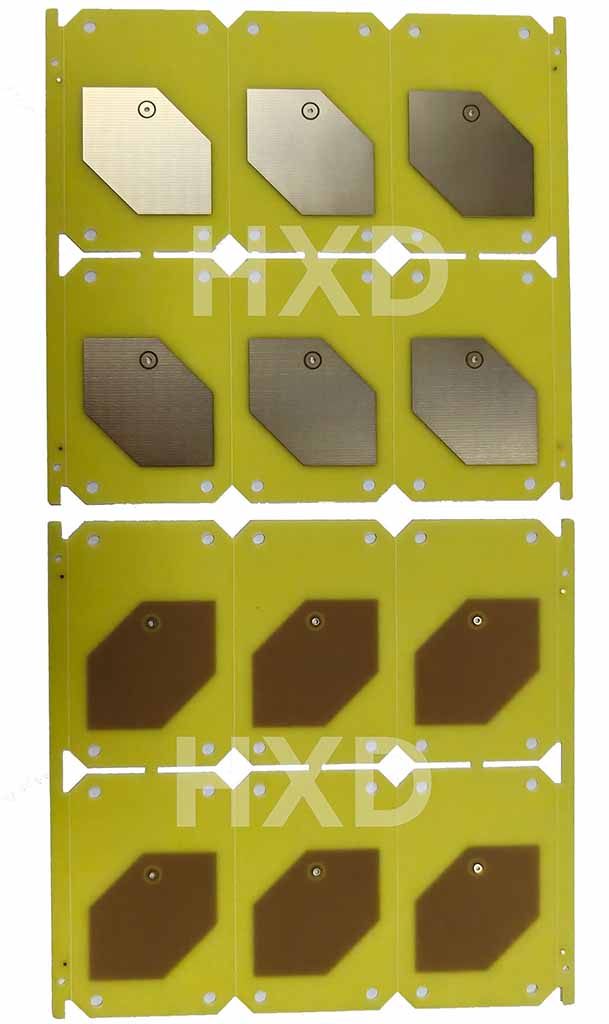

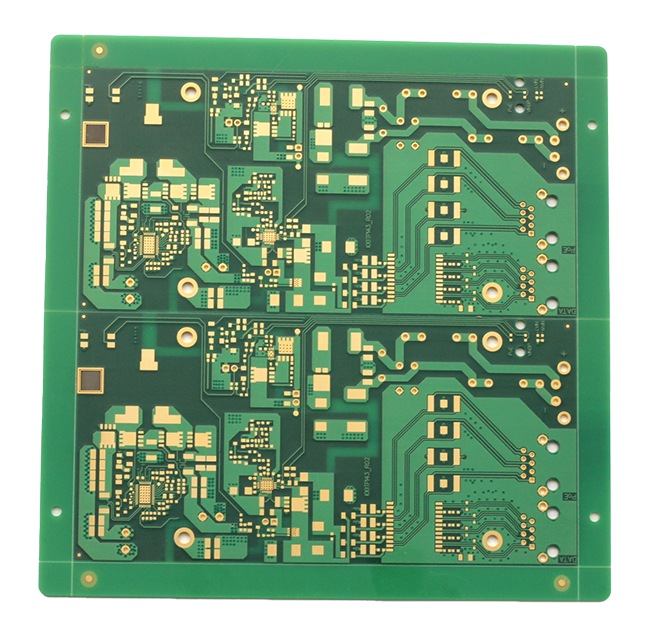

Mature Mass Production

HXD has full manufacturing experience in Rigid PCB production. Through continuous optimization of panel design and process efficiency, we effectively improve the material utilization. We can ensure the stable quality for mass volume.

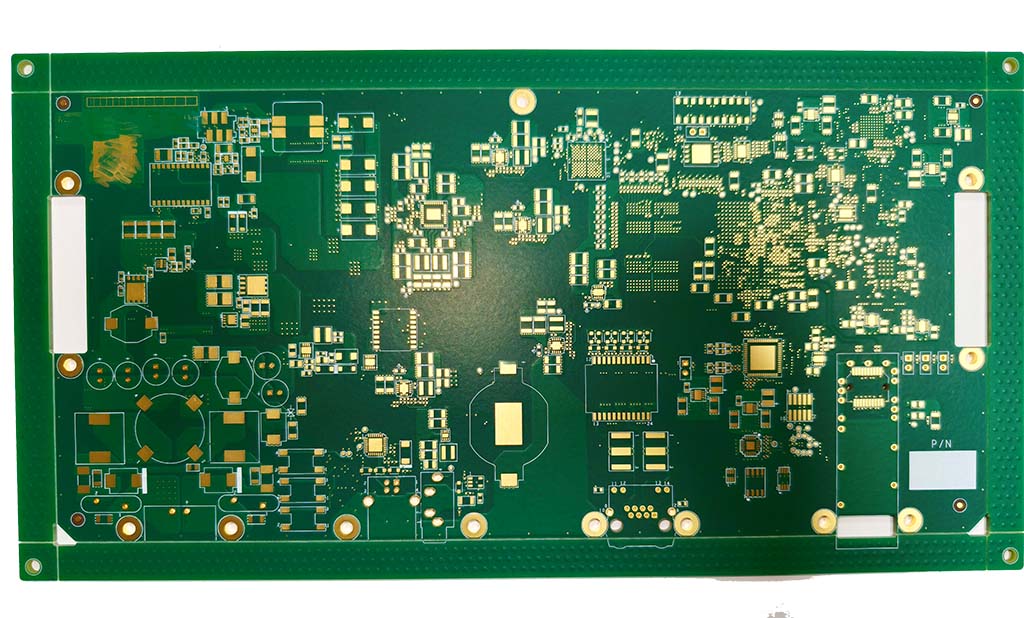

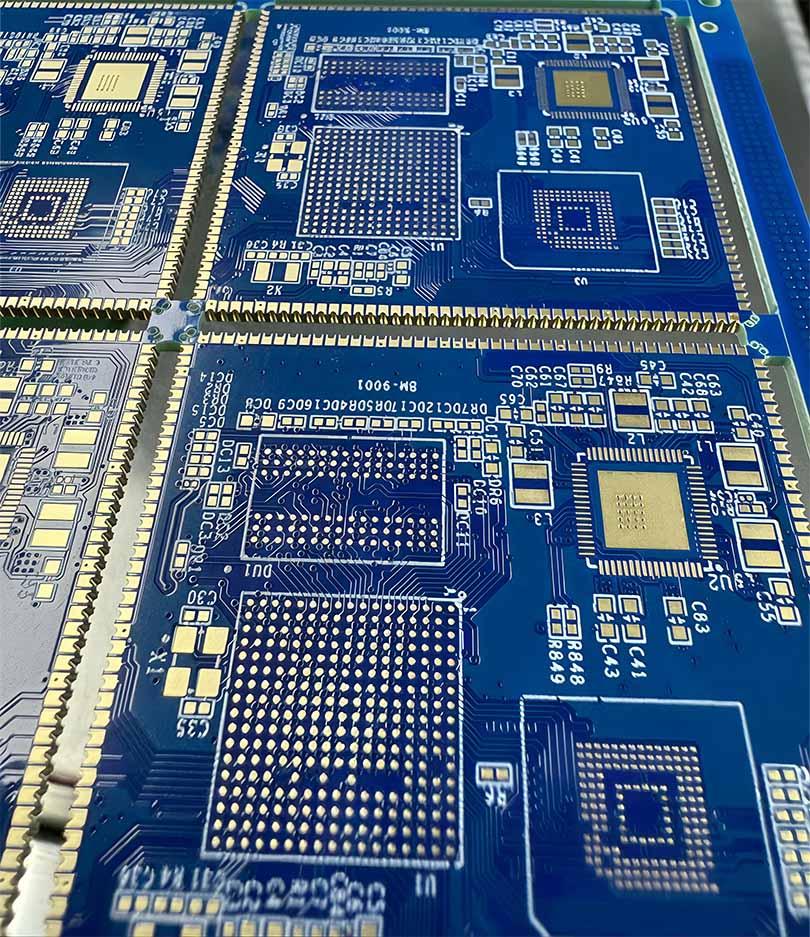

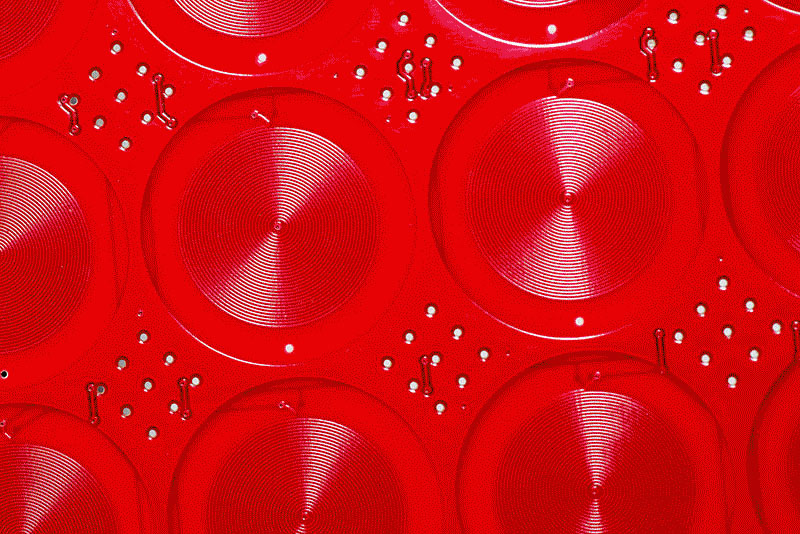

Multilayer Capability

Rigid PCBs vary from single-layer and double-layer structures to complex multi-layer structures. It can flexibly meet different circuit design and functional integration needs. HXD has mature production processes, enabling good quality control of lamination, hole plating, and circuit processing. By this way, it can achieve high-density wiring and high-reliability connections.