Why Choose Double-sided PCBs?

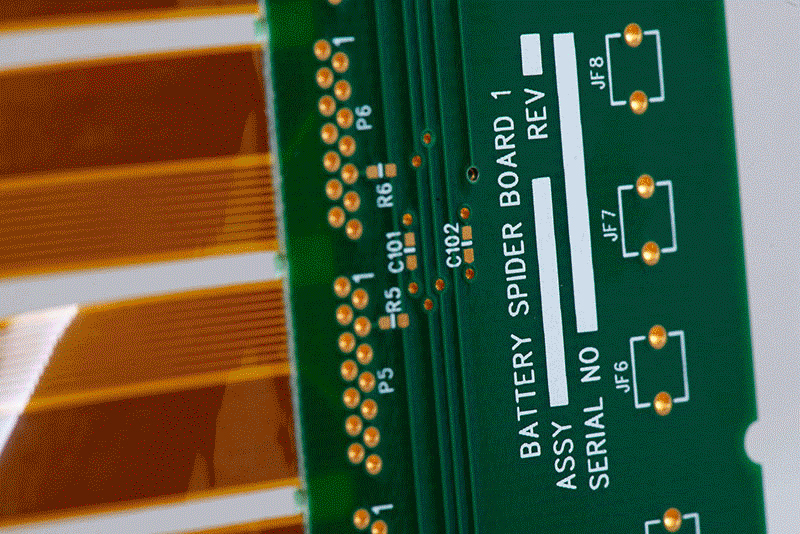

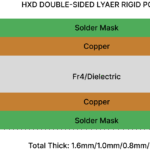

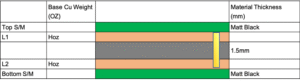

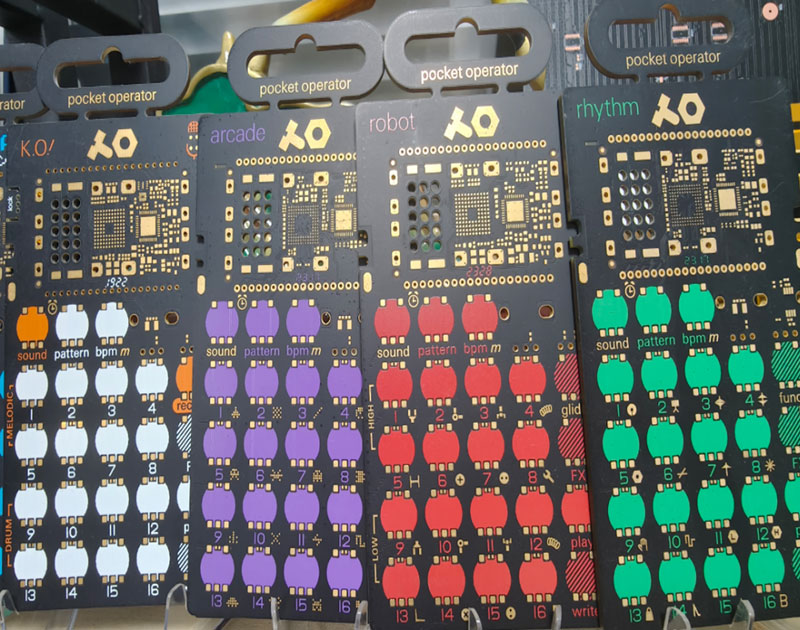

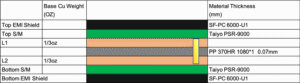

A Double-sided PCB( 2-Layer PCB) has conductive copper layers on both the top and bottom, with an insulating base material (usually FR-4) in the middle. It connects the circuits on both sides through Plated Through Holes (Vias), allowing signals to travel between layers.Double-sided PCBs offer the following advantages:

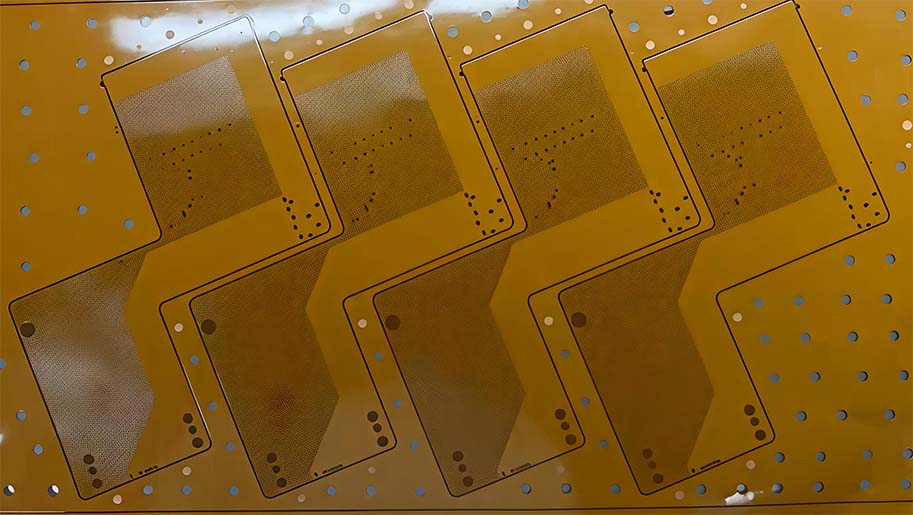

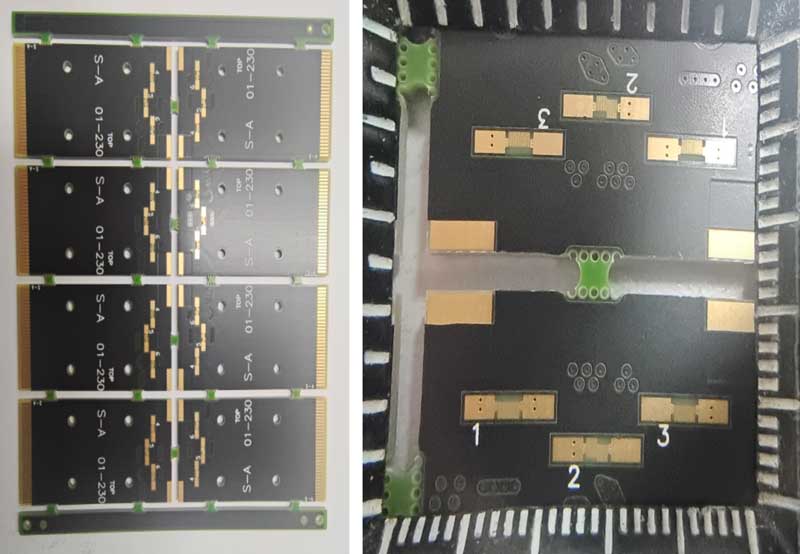

Low Cost: Double-sided PCBs use less material and have a simple manufacturing process. This makes them the most cost-effective choice.They are cost-effective for mass production.

Simple circuits: If your design has few components and signal lines, a single or double-sided layout is enough without extra internal layers.

Fast delivery: Double-sided PCBs have a simpler manufacturing process with fewer steps, resulting in shorter lead times. For 2-Layer Prototypes,HXD can support you 24–48 hours lead time.

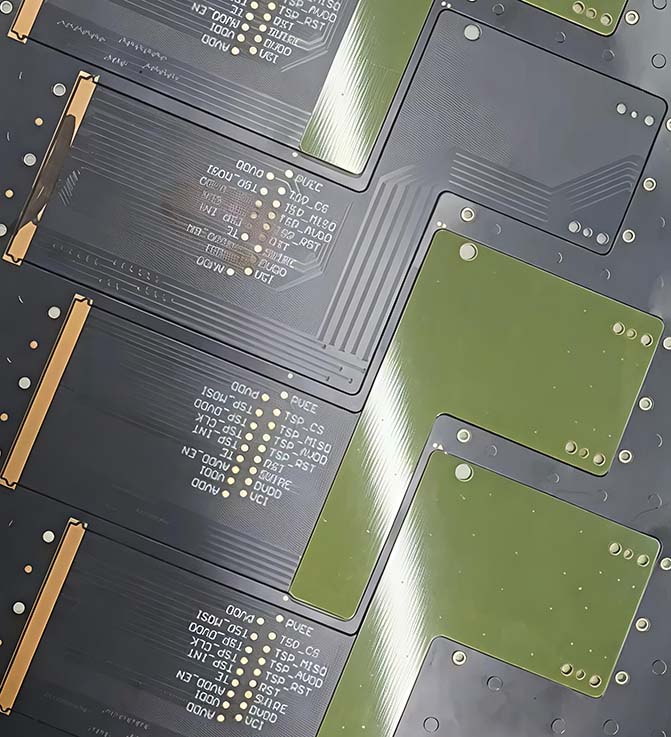

Easy maintenance :Circuit traces are clearly visible on double-sided boards. This makes it much easier to debug, repair, or solder components by hand compared to complex boards.

If your design has limited space or involves high-speed digital signals, a Double-sided PCB is your best choice. However, if your design has very limited space or uses high-speed signals, you should consider a 4-layer or multilayer board.