What is Rigid-Flex PCB?

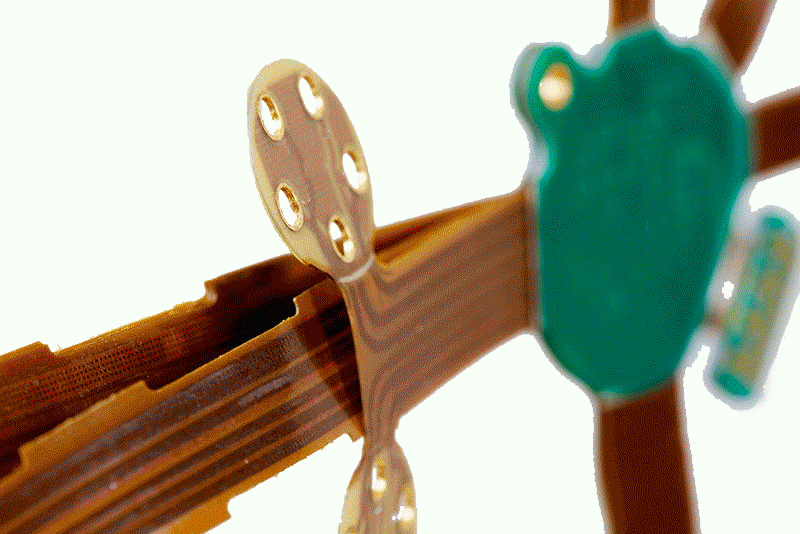

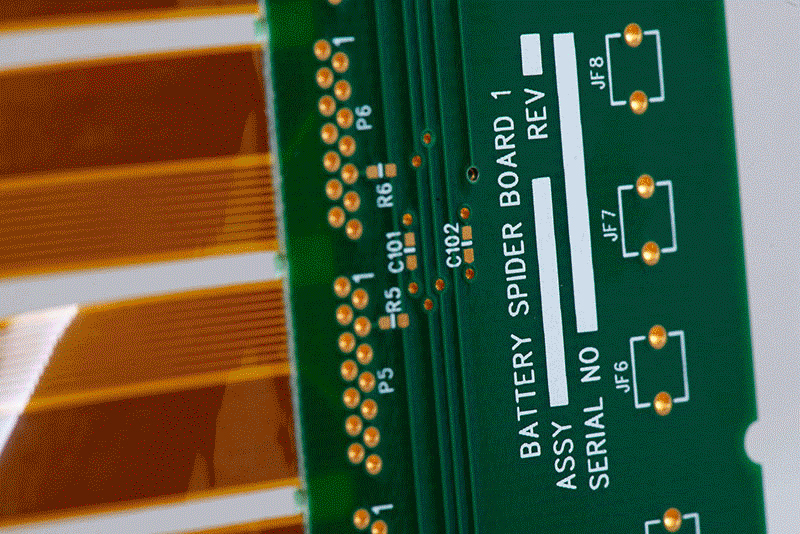

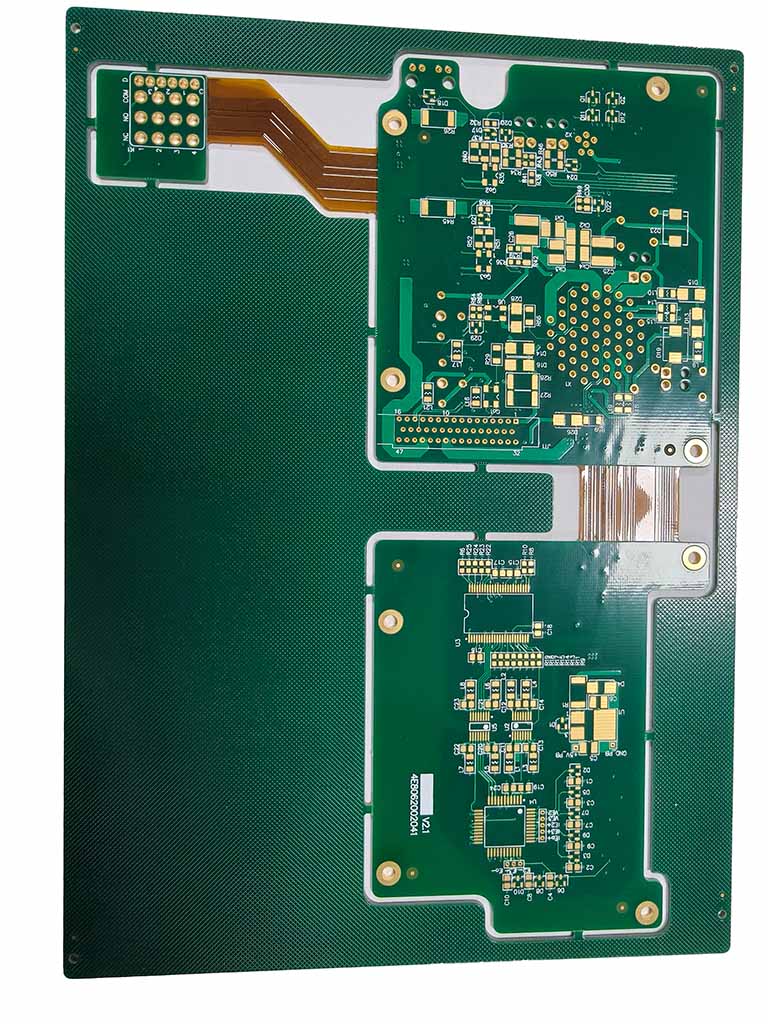

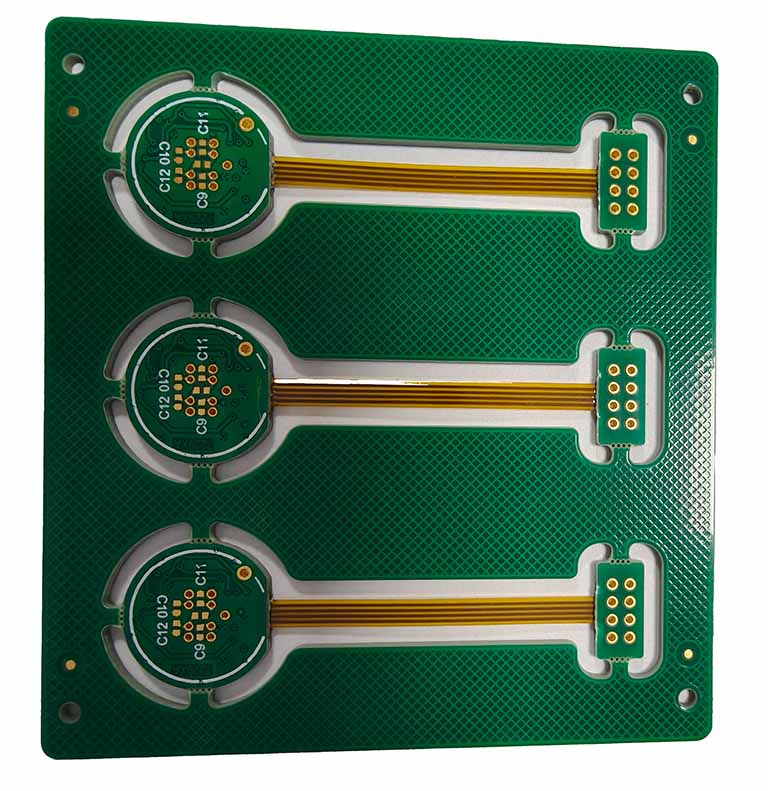

A Rigid-Flex circuit board (RFPCB) is a special type of PCB that combine the Rigid PCB and flex PCB through a lamination process. It doesn’t need additional connectors or solder joints. By this way, it can provid greater design freedom for complex electronic systems.

Rigid-Flex PCBs are widely used in applications with strict requirements for reliability, space utilization, and weight reduction. It’s always applied in some high requirement industries, such as drones and medical equipment.

Advantages of Rigid-Flex PCBs over standard PCBs:

1.Integrated design: The rigid and flexible sections are tightly integrated. It can eliminate the need for additional connectors or wiring harnesses.

2.Adaptability to complex spaces: The flexible part can be folded or bent in three dimensions, saving space.

3.High reliability: Due to the reduction of solder joints, cables, and connectors, the risk of system failure is significantly reduced. Especially it is better in environments with vibration, shock, and temperature changes.

4.Excellent electrical performance: Shorter signal paths reduce impedance discontinuities and signal loss. It can improve signal integrity.

Although the cost of rigid-flex PCBs may be higher than standard FR4 PCB or Flex PCB. Considering their overall advantages, they are often a more cost-effective solution.